Capacitive touch sensors..

(are cool..)

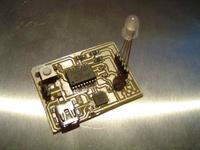

Sensor board back and front.

For my boat's interior I figured that LED strips would be just right in terms (low) power use lighting. The LED strips are mounted so that they provide indirect light and to switch them ON and OFF I wanted invisible 'hot' spots on the wooden side cabinets.

First thing that came to my mind was to use a QT118. I've used this chip before and it's proven to be a reliable capacitive touch interface.

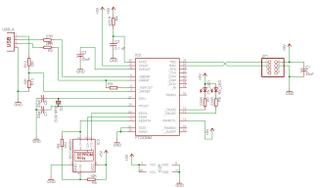

As the diagram shows, not many components are required to make it work.

And the resulting PCB..

These two boards are mounted to the back of the cabinet facia. A strip of aluminum tape connected to the board acts as the interfacing / sensing area.

All solid state, no moving contacts. Self adjusting, automatic gain. Capable of switching somewhere around 8A. (more than enough..)

AT42QT1012 vs. QT118

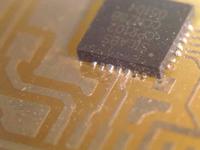

Atmel now retired the previous QProx QT11x series and put the AT42QT1012 in place as the QT118's successor. It comes in a very small package (SOT23-6) which could lead to smaller board design compared to the SO-8 package that houses the QT118.

So I designed a board for the newer part first and found that I could not get it to work as reliable as the QT118, a pity... More experimenting probably needed..

Still having two QT118's in my stock I figured that, although it's now oboslete, it was still worth a board design.

A round PCB, why not.

The PCB has an integrated sensing area, so the board can be used directly behind a dielectric surface. In the end I decided to connect to a remote sensing surface.

(are cool..)

Sensor board back and front.

For my boat's interior I figured that LED strips would be just right in terms (low) power use lighting. The LED strips are mounted so that they provide indirect light and to switch them ON and OFF I wanted invisible 'hot' spots on the wooden side cabinets.

First thing that came to my mind was to use a QT118. I've used this chip before and it's proven to be a reliable capacitive touch interface.

As the diagram shows, not many components are required to make it work.

And the resulting PCB..

These two boards are mounted to the back of the cabinet facia. A strip of aluminum tape connected to the board acts as the interfacing / sensing area.

All solid state, no moving contacts. Self adjusting, automatic gain. Capable of switching somewhere around 8A. (more than enough..)

AT42QT1012 vs. QT118

Atmel now retired the previous QProx QT11x series and put the AT42QT1012 in place as the QT118's successor. It comes in a very small package (SOT23-6) which could lead to smaller board design compared to the SO-8 package that houses the QT118.

So I designed a board for the newer part first and found that I could not get it to work as reliable as the QT118, a pity... More experimenting probably needed..

Still having two QT118's in my stock I figured that, although it's now oboslete, it was still worth a board design.

A round PCB, why not.